Imagine a world where buildings can be designed, constructed, and transformed at an unprecedented pace. Where architects and engineers can bring their most ambitious visions to life, limited only by their imagination.

Welcome to the era of 3D printing in construction, where the boundaries of innovation are being pushed to new heights. With its unparalleled speed, efficiency, and design flexibility, 3D printing is revolutionizing the way we build, and the future of construction has never looked brighter.

In this article, we will explore the exciting possibilities of 3D printing in construction and how it is poised to transform the industry forever.

The Rise of 3D Printing in Construction

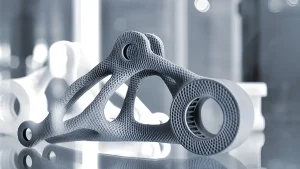

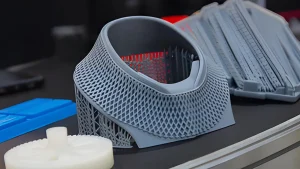

3D printing, also known as additive manufacturing, has found its way into the construction industry, allowing builders to create structures layer by layer. This technology has evolved rapidly over the past decade, enabling new possibilities in house construction and infrastructure development.

Benefits of 3D Printed Construction

- Speed and Efficiency: One of the standout benefits of 3D printing is its ability to significantly reduce construction time. Traditional construction methods can take months, while 3D printed structures are typically completed in a matter of days.??

- Cost-Effectiveness: By minimizing labor costs and reducing material waste, 3D printing can lead to substantial savings for construction projects.??

- Design Flexibility: The possibilities of design with 3D printing are virtually limitless. Builders can create complex forms and structures that would be prohibitively expensive or difficult to achieve using conventional methods.?

Notable 3D Printing Projects

Companies like ICON and Apis Cor are leading the charge in 3D printed homes. ICON’s popular housing projects demonstrate how this technology can provide quick shelter solutions, especially in disaster-affected areas. Meanwhile, Apis Cor gained attention for printing a house in just 24 hours, showcasing the potential for rapid construction.?

Concerns about Structural Integrity

Despite its advantages, 3D printing in construction raises questions about material properties and load capacity. The materials used in 3D printing, such as concrete and polymers, have varying structural properties that can affect a building’s ability to withstand environmental loads, such as wind and earthquakes. For example, concrete has high compressive strength but can be brittle and prone to cracking, while polymers can be flexible but do not offer the same level of structural integrity as traditional materials.

Innovations and Future Directions

To address these challenges, ongoing research is focused on developing advanced materials that improve structural integrity and meet building codes. Test protocols include static and dynamic testing, such as compression, tension, and flexion tests, as well as environmental testing, such as exposure to moisture and temperature fluctuations.

Additionally, technologies like simulation software and AI can predict performance and ensure compliance before construction begins. Collaboration between 3D printing companies and regulatory bodies is essential to create updated standards and guidelines.

By promoting innovation and collaboration, the construction industry can unlock the full potential of 3D printing to build structures that bring imagination to life.

Join us at Raymankind to discover how we can help you build the future!?