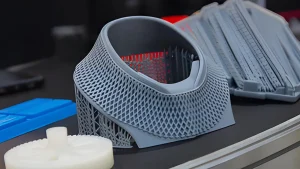

In today’s fast-paced manufacturing landscape, the ability to produce tools and components rapidly is crucial for maintaining a competitive edge. 3D printing, also known as additive manufacturing, is revolutionizing rapid tooling processes, enabling the creation of complex and customized tools in a fraction of the time required by traditional methods. Beyond reducing lead times and facilitating complex designs, this technology offers greater design flexibility, allowing the production of geometries unachievable with conventional machining techniques.

Advantages

One of the most significant advantages of 3D printing for rapid tooling is the drastic reduction in production time. Traditional tooling methods can take weeks or even months to deliver, while 3D printing can produce parts within hours. This speed enables manufacturers to respond swiftly to market demands, innovate faster, and significantly reduce the time it takes to launch new products.

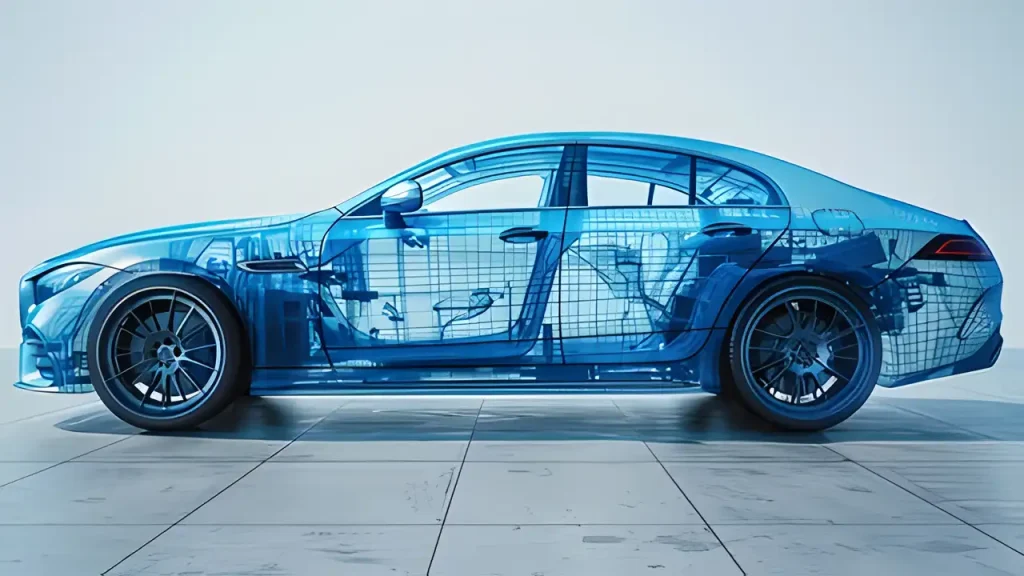

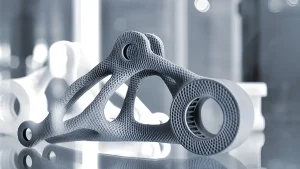

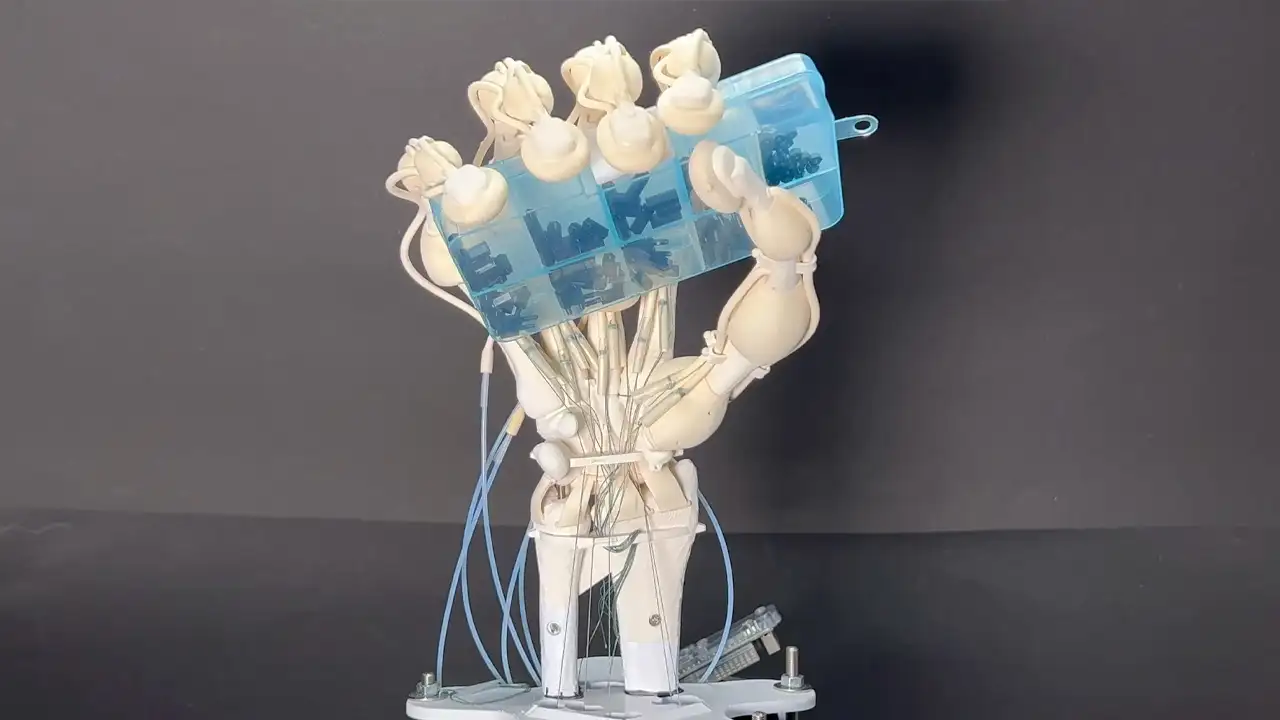

Additionally, 3D printing allows the creation of lightweight and complex geometries that can enhance tool performance. For example, tools can be designed with cooling channels or specific shapes that optimize functionality and reduce weight, leading to more efficient operations. This flexibility caters to the specific demands of sectors like automotive and aerospace, where rapid design changes and adaptation are essential.

Beyond significant time savings, 3D printing for rapid tooling offers financial and operational advantages. Additive manufacturing substantially reduces material costs by producing parts with minimal waste, using only the material necessary to create the item. This is especially beneficial in industrial processes where material costs are high and waste must be minimized.

Another key point is the integration of 3D printing with digital processes. The ability to connect directly with modeling and simulation software enables immediate adjustments during the design phase, significantly reducing the time between initial creation and final production, while enhancing precision and reducing prototyping cycles. Additionally, 3D printing reduces costs associated with prototyping and testing, allowing for rapid modifications before final implementation and enabling cost and material optimization.

Another important benefit is the ability to customize tools. With 3D printing, manufacturers can quickly adapt designs to meet specific project requirements, making the technology ideal for sectors that demand flexible, tailor-made solutions.

Sustainability is also a critical advantage; by reducing material waste and enabling the use of recyclable inputs, 3D printing contributes to eco-friendly production, aligning with industrial practices increasingly focused on minimizing environmental impact. These benefits make additive manufacturing a strategic tool in modern production, offering solutions to the demands for agility, precision, and adaptability in industrial processes.

Statistics to Consider

A report by Wohlers Associates from 2023 revealed that the global market for 3D printing, including additive manufacturing for tooling, is projected to surpass $34 billion by 2026, with a compound annual growth rate (CAGR) of 23%. This trend illustrates the growing adoption of 3D printing across industries such as automotive, aerospace, and healthcare, where the demand for efficiency and customization is high.

This growth is further driven by advances in printing technologies and material developments, which are crucial to addressing durability and performance concerns associated with produced parts. The rising interest in sustainable solutions is also motivating more companies to explore 3D printing as they seek to reduce waste and production costs. This market transformation demonstrates that 3D printing is not just a passing trend but a significant shift in how tools and components are manufactured.

Conclusion

3D printing is driving a true revolution in rapid tooling, shaping a future where innovation and agility have become essential. This technology not only optimizes production but also challenges traditional norms, enabling manufacturers to create customized and complex solutions in an agile and cost-effective manner.??

However, for this transformation to be sustainable, it is essential for companies to remain vigilant about the durability and feasibility of the tools produced. By selecting high-performance materials and understanding the nuances of 3D design, organizations can not only harness the advantages of this disruptive technology but also position themselves as leaders in a rapidly evolving market.

Furthermore, the growing adoption of 3D printing in sectors like healthcare and construction highlights the versatility and need for continuous innovation. With the expectation that the 3D printing market will continue to expand, companies that strategically embrace this approach will stay ahead, transforming challenges into opportunities.