Multimaterial 3D printing represents a revolution in product design and manufacturing, enabling the creation of complex forms with a variety of materials in a single print process. This technology allows designers and engineers to push new boundaries by combining materials with distinct physical properties, achieving highly functional and aesthetically advanced products.

The Potential of Multimaterial Printing

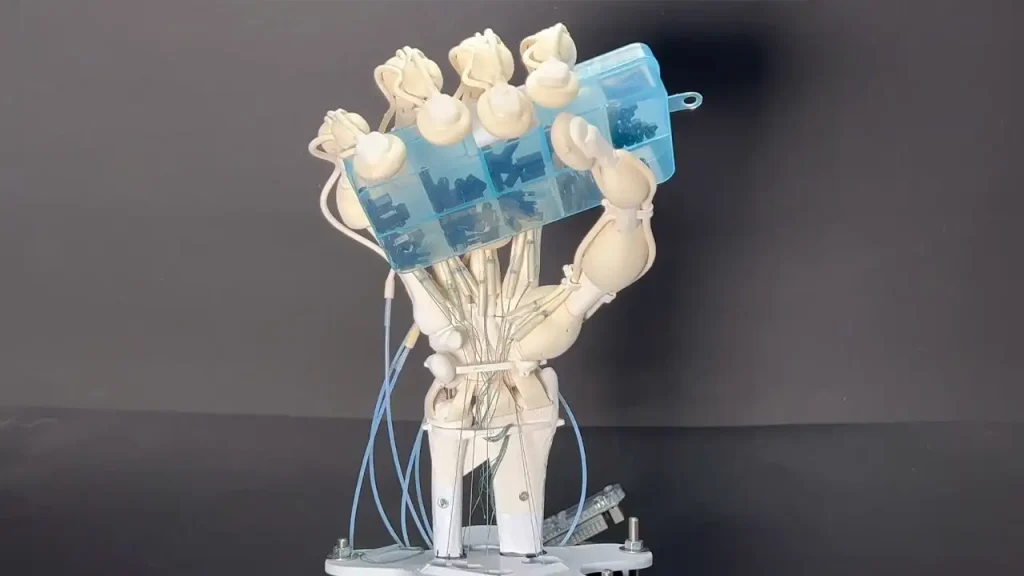

Imagine the creative possibilities of combining flexible, rigid, transparent, or even conductive materials in a single part. Multimaterial 3D printing enables the integration of various functionalities into a single design, expanding the potential for customization and adaptation across industries. For example, by blending hard plastics with soft-touch materials, it’s possible to produce items that are both structurally solid and comfortable to handle—an ideal solution for sectors like automotive, healthcare, and consumer goods.

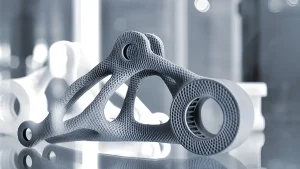

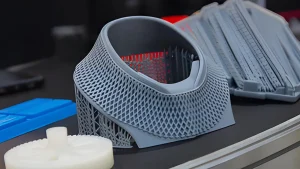

Multimaterial 3D printing technology is a powerful tool for innovative projects, helping industries such as automotive, healthcare, and electronics create components with multiple properties in a single piece. In the automotive sector, for example, it’s possible to produce parts that combine mechanical strength with impact-absorbing elements in specific areas, enhancing user safety and comfort. In healthcare, 3D multimaterial printing enables the creation of custom medical devices like prosthetics that combine structural rigidity with flexible areas for improved comfort and patient fit.

Additionally, using conductive materials alongside traditional plastics opens up new possibilities for integrated electronic devices, enabling the creation of sensors and circuits directly within complex designs. The global interest in this capability is evident, with studies predicting significant growth in the multimaterial 3D printing market. According to SmarTech Analysis, the sector is expected to reach $2.1 billion by 2025, highlighting the rising demand for solutions that merge physical properties in complex designs.

Opportunities and Advances in Multimaterial Printing

Although 3D multimaterial printing initially presented technical challenges, it is now entering an exciting phase of expansion and enhancement. While material compatibility still requires attention, advances in formulations and specific adhesives are enabling more efficient bonding between different materials. These improvements allow for more robust and secure designs, reducing the risk of structural failure, especially in applications requiring strong bonds between rigid and flexible materials.

Another area of development is in the thermal properties of materials. Although variations in expansion rates still present challenges, new technologies and real-time thermal control software now adjust print parameters dynamically, minimizing the risk of warping and delamination. This progress, coupled with advanced simulation tools, allows engineers to predict and address potential issues with greater precision.

On the durability front, while some users have reported wear-related issues, new testing methods and quality standards are continually being implemented, reinforcing the reliability of final products. Furthermore, partnerships between material manufacturers and 3D printing companies are facilitating the development of hybrid materials specially designed for stronger adhesion, creating more resilient multimaterial products for demanding industries like automotive, medical, and aerospace.

The continuous evolution of this field points to an optimistic future where challenges are transformed into innovation opportunities, making multimaterial printing increasingly accessible, reliable, and functional for complex designs in a range of sectors.

Exploring the Future of Multimaterial Printing

In conclusion, multimaterial 3D printing stands out as a cutting-edge technology with significant potential to transform complex product design across multiple industries. Although technical challenges remain, recent innovations and the ongoing development of compatible materials and advanced control methods indicate that these obstacles are rapidly being overcome.

This technology not only offers a greater degree of customization and functionality but is also proving more viable and practical for real-world applications. The future of multimaterial 3D printing is promising, driven by growing demand and continuous innovation.

For the latest advancements in 3D printing, visit Raymankind and discover how this technology can bring your ideas to life.?