Medical & Healthcare Industry with Raymankind’s 3D Printing Technology

The Medical & Healthcare industry is continually advancing, driven by the need for innovative solutions that enhance patient care, streamline medical processes, and reduce costs. 3D printing technology, as offered by Raymankind, is at the forefront of these advancements, transforming how medical devices, prosthetics, and other healthcare products are designed and manufactured. Let’s explore how our state-of-the-art 3D printing services can benefit the Medical & Healthcare industry.

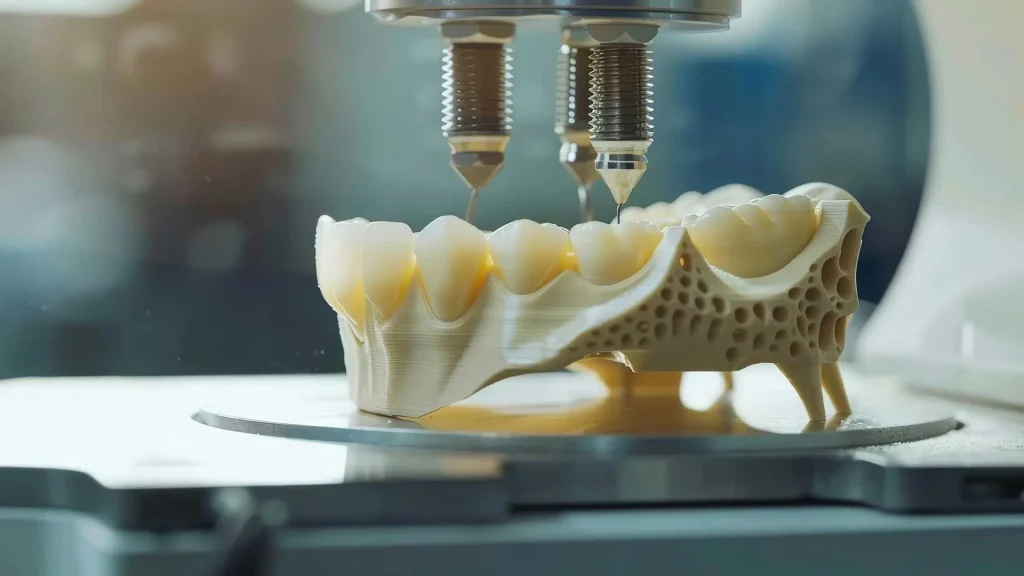

Personalized Medical Devices and Prosthetics

3D printing offers unparalleled opportunities for the customization and personalization of medical devices and prosthetics. Each patient is unique, and 3D printing allows for the creation of devices tailored to individual anatomical structures. This personalization ensures a better fit, increased comfort, and improved functionality for patients.

For instance, prosthetic limbs can be custom-made to match the precise dimensions of a patient’s residual limb, enhancing the fit and reducing the need for adjustments. Similarly, 3D-printed hearing aids, dental implants, and orthotic devices can be designed to fit perfectly, leading to better outcomes and higher patient satisfaction.

Accelerating Innovation with Rapid Prototyping

In the medical field, the ability to quickly prototype and test new devices is crucial. 3D printing enables rapid prototyping, allowing medical device manufacturers and researchers to quickly produce and evaluate new designs. This rapid iteration process speeds up the development cycle, ensuring that innovative solutions reach healthcare providers and patients faster.

Raymankind’s 3D printing services support the development of a wide range of medical products, from surgical instruments to diagnostic tools. By facilitating rapid prototyping, we help accelerate the innovation process, bringing cutting-edge medical technologies to market more swiftly and efficiently.

Cost-Effective Manufacturing

Traditional manufacturing methods for medical devices often involve high costs due to the need for specialized tooling and molds. 3D printing eliminates these expenses, making the production of medical devices more cost-effective, particularly for small production runs or custom devices. This cost reduction can be especially beneficial for developing new medical technologies and making them accessible to a broader range of healthcare providers.

Additionally, 3D printing enables on-demand manufacturing, reducing the need for large inventories and minimizing waste. Healthcare providers can produce devices and components as needed, ensuring timely delivery and reducing storage costs.

Enhanced Surgical Planning and Training

3D printing plays a crucial role in surgical planning and medical training. By creating accurate anatomical models based on patient-specific imaging data, surgeons can plan complex procedures with greater precision. These models provide a tangible reference, allowing surgeons to visualize and rehearse surgeries before performing them on patients, ultimately improving surgical outcomes.

Medical students and professionals can also benefit from 3D-printed models for training purposes. These models provide a realistic and hands-on learning experience, enhancing their understanding of human anatomy and surgical techniques.

Patient-centered future

The integration of 3D printing into the Medical & Healthcare industry is driving significant advancements in patient care, medical device innovation, and surgical planning. From personalized medical devices and rapid prototyping to cost-effective manufacturing, the benefits of 3D printing are transformative.