Precision and Efficiency: Plastic Injection Molding Services by Raymankind

Plastic injection molding is a cornerstone of modern manufacturing, offering unmatched precision, efficiency, and scalability. At Raymankind, we provide state-of-the-art plastic injection molding services that cater to a wide range of industries. Our advanced technology and expertise ensure that your products are manufactured to the highest standards of quality and performance. Discover how our plastic injection molding services can elevate your manufacturing process and deliver exceptional results.

What is Plastic Injection Molding?

Plastic injection molding is a manufacturing process that involves injecting molten plastic into a mold to create a wide variety of parts and products. This method is highly efficient and capable of producing complex shapes with high precision and consistency. It’s ideal for both high-volume production runs and the creation of intricate components.

Benefits of Plastic Injection Molding

High Precision and Quality

Plastic injection molding offers exceptional precision, allowing for the production of highly detailed and complex parts. The process ensures consistent quality across large production runs, making it ideal for applications that require tight tolerances and high standards of accuracy.

Efficiency and Scalability

Injection molding is highly efficient, enabling the rapid production of parts in large quantities. The process is well-suited for high-volume manufacturing, providing significant cost savings on large production runs. Its scalability makes it a preferred choice for industries that demand consistent output and quick turnaround times.

Versatility in Material and Design

The versatility of plastic injection molding extends to both the materials used and the designs it can accommodate. A wide range of thermoplastics can be used in the process, each offering different properties to suit specific applications. Additionally, the technology allows for the creation of complex shapes, varying wall thicknesses, and intricate details, providing flexibility in design and functionality.

Durability and Strength

Parts produced through plastic injection molding are known for their durability and strength. The process ensures that the finished products are robust and capable of withstanding demanding environments and usage conditions. This makes it ideal for applications that require reliable and long-lasting components.

Industry Applications

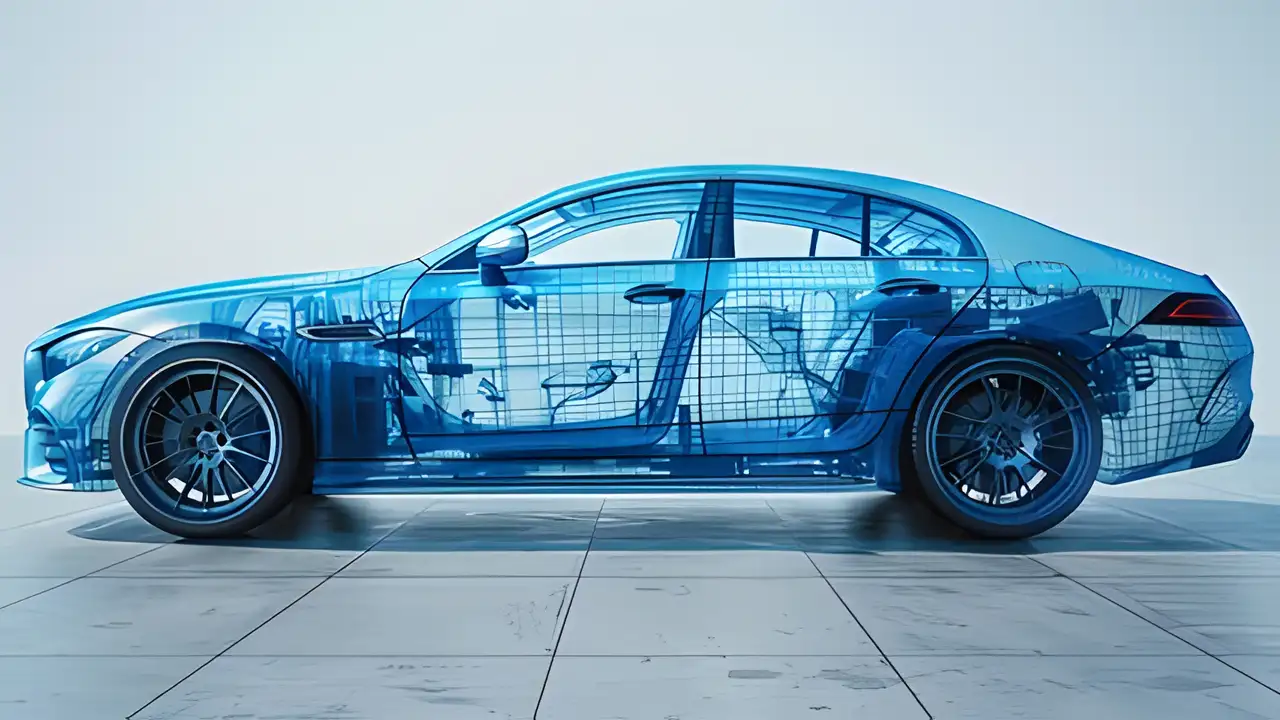

Automotive

In the automotive industry, precision and durability are crucial. Plastic injection molding is used to manufacture a wide range of automotive parts, from interior components to under-the-hood applications. The ability to produce lightweight yet strong parts contributes to overall vehicle efficiency and performance.

Consumer Goods

For consumer products, quality and consistency are key. Injection molding enables the mass production of high-quality plastic parts used in everyday items such as household appliances, electronics, and toys. The efficiency of the process ensures that products can be brought to market quickly and cost-effectively.

Electronics

In the electronics industry, the miniaturization and complexity of components require precise manufacturing techniques. Injection molding is used to create housings, connectors, and other critical parts that ensure the functionality and reliability of electronic devices. The technology supports the production of intricate designs and fine details essential for modern electronics.

Packaging

Packaging solutions benefit from the efficiency and versatility of plastic injection molding. The process is used to produce containers, caps, and closures that are durable, lightweight, and cost-effective. Injection molding enables the creation of custom packaging designs that meet specific product and branding requirements.

Why Choose Raymankind for Plastic Injection Molding?

Expertise and Experience

Raymankind brings extensive experience in plastic injection molding, providing high-quality solutions tailored to your specific needs. Our team of experts is dedicated to delivering precise and reliable results that meet the highest standards of quality and performance.

Advanced Technology

We utilize the latest injection molding technologies and materials to ensure optimal performance and efficiency. Our state-of-the-art equipment and techniques enable us to tackle complex projects with confidence and precision.

Customization and Flexibility

At Raymankind, we understand that each project is unique. Our customized approach ensures that your specific requirements are met, providing you with personalized solutions that enhance your manufacturing process and product quality.

Commitment to Quality

Quality is at the core of everything we do. We are committed to delivering exceptional products that meet the highest standards of performance and reliability. Our rigorous quality control processes ensure that every component we produce is flawless.