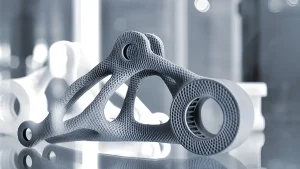

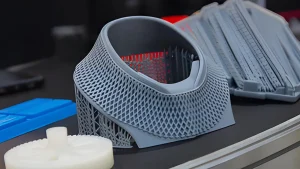

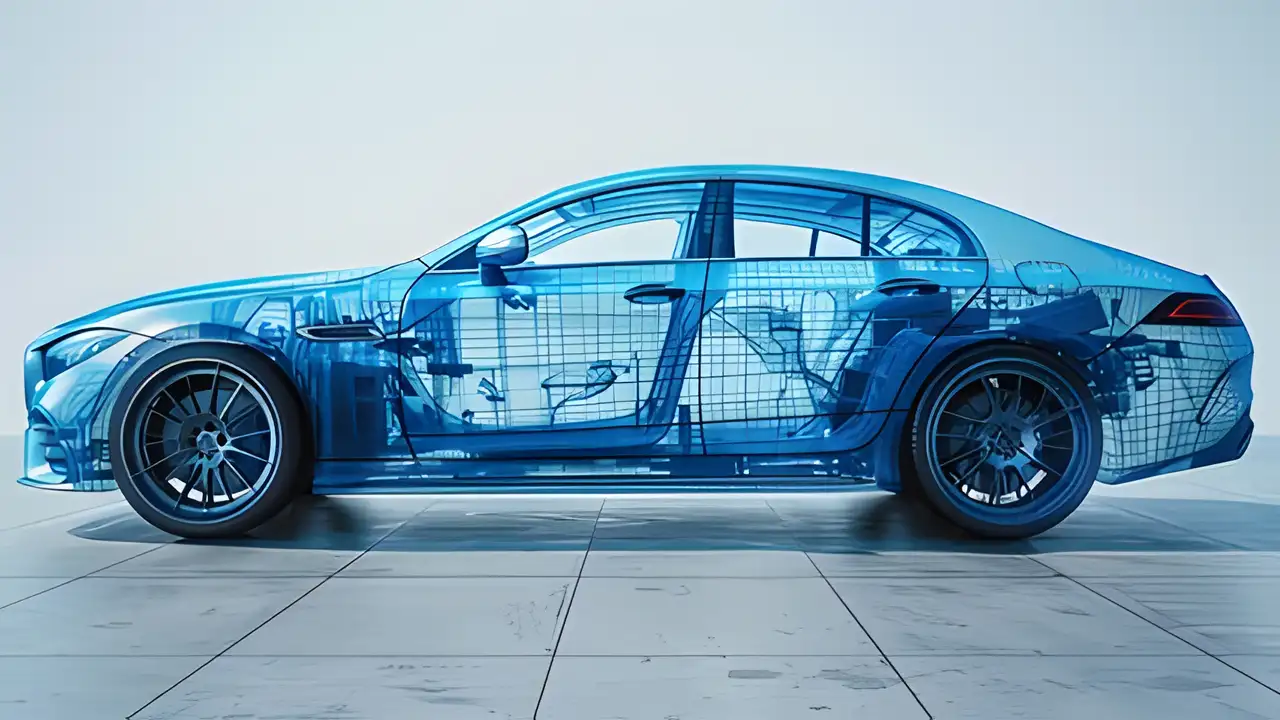

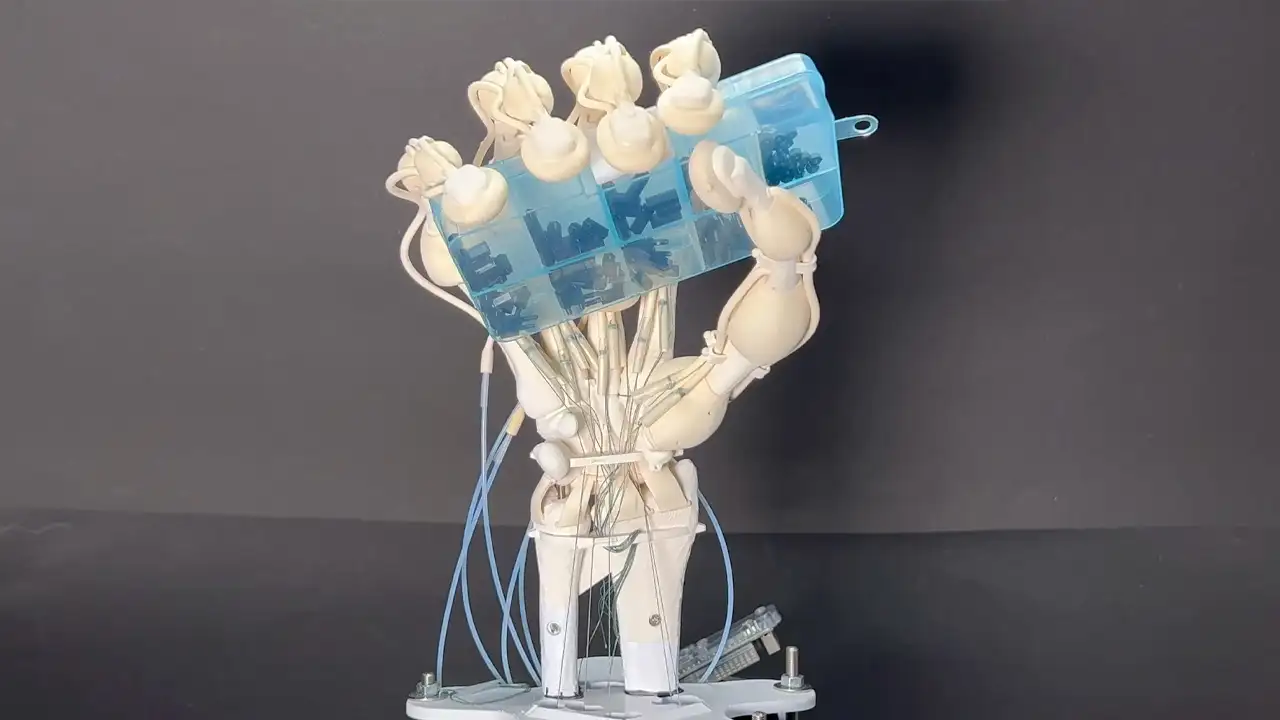

As a leading provider of top-notch 3D printing services, rapid prototyping to full-scale production in various industries such as toys and entertainment, healthcare, footwear and fashion, robotics and drones, consumer products and automotive, Raymankind understands the importance of achieving high-resolution prints. In this article, we’ll dive into the advanced level information on how to optimize print quality, from selecting the right printer and materials to understanding settings and maintenance tips.

Importance of Printer Calibration

Regularly calibrating your 3D printer is crucial for optimal results. This includes bed leveling, nozzle alignment, and fine-tuning. For resin machines, calibration is especially important as it affects the accuracy of layer formation. By ensuring proper calibration, you’ll minimize errors and achieve consistent print quality.

Choosing the Right Material

Different materials have varying impacts on print quality. PLA and ABS filaments are popular choices for beginners, while resins offer higher resolution and detail. When choosing a material, consider factors like detail, strength, and finish to select the best option for your project.?

Layer Height and Print Speed

Adjusting layer height and print speed affects resolution and surface smoothness. A lower layer height typically results in higher resolution prints, while faster print speeds can lead to smoother surfaces. Finding the ideal balance between these factors is crucial for achieving high-quality prints.

Using Quality Materials and Consumables

High-quality materials are essential for optimal print quality. Premium materials like those offered by Raymankind’s consumable range provide benefits such as reduced inconsistencies, ensuring a smooth printing experience.

Post-Processing Techniques

Simple post-processing techniques like sanding, polishing, and painting can enhance the appearance of your prints. Advanced techniques like vapor smoothing for ABS materials can further refine surface finish. Expertise in curing the resin printed material ensures a perfect finish for your print.

Common Troubleshooting Tips

Warping, stringing, and layer separation are common print quality issues that can be easily addressed with simple fixes. For resin printing, errors such as delamination or uneven curing can occur; understanding the causes of these issues is key to resolving them.

Achieving high-resolution 3D prints requires attention to detail in printer calibration, material selection, layer height and print speed adjustments, use of quality materials and consumables, post-processing techniques, and troubleshooting common errors. By following these tips, you’ll be well on your way to producing exceptional prints that meet the demands of various industries.

Join the 3D printing revolution with Raymankind – discover new possibilities and take your projects to the next level!?