The footwear industry is experiencing a transformative shift, thanks to advancements in 3D printing technology. This innovative approach is not only enhancing how shoes are designed and manufactured but also setting new standards for customization, sustainability, and efficiency.?

The Rise of 3D Printing in Footwear

3D printing, or additive manufacturing, involves creating three-dimensional objects from digital files by layering materials. In the footwear industry, this technology is redefining traditional manufacturing processes, allowing for unprecedented levels of personalization and efficiency.

Why Innovation Matters

In a market driven by changing consumer preferences and the demand for unique products, innovation is crucial. 3D printing offers a way to keep pace with these demands by enabling rapid customization and design flexibility, addressing both aesthetic and functional needs.

Customizable Footwear

Personalized Fit: One of the standout benefits of 3D printing is the ability to create shoes that perfectly fit individual foot shapes and sizes. This customization ensures enhanced comfort and reduces the need for adjustments.

Design Flexibility: With 3D printing, customers can choose from a wide range of designs, patterns, and colors, turning their unique ideas into reality. This level of personalization was previously unattainable with traditional manufacturing methods.

Rapid Prototyping and Design Iteration

Faster Prototyping: 3D printing accelerates the prototyping process, allowing designers to quickly create and test new shoe concepts. This speed is crucial for keeping up with fast fashion trends and reducing time to market.

Design Iterations: The technology also facilitates iterative design, enabling continuous refinement of prototypes without the need for extensive retooling. This results in more innovative and well-tested products.

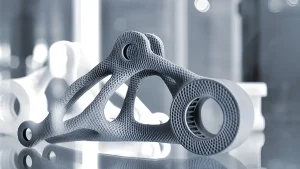

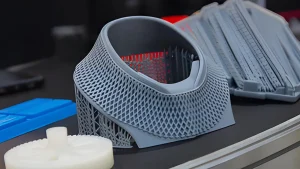

Complex Geometries and Innovative Designs

Unique Structures: 3D printing allows for the creation of intricate and complex geometries that are challenging to achieve with traditional methods. This opens up possibilities for more innovative and aesthetically striking footwear designs.

Innovative Materials: Advanced materials used in 3D printing, such as flexible filaments and bio-based composites, enhance the functionality and appeal of footwear, offering new solutions for durability and comfort.

Sustainable Manufacturing

Reduced Waste: Unlike traditional manufacturing processes, which often result in substantial material waste, 3D printing uses only the necessary amount of material, significantly reducing waste.

Eco-Friendly Materials: The industry is also exploring sustainable materials that align with environmental goals, such as biodegradable and recycled filaments, making footwear production greener.

On-Demand Production and Inventory Management

Made-to-Order Production: 3D printing supports on-demand production, which minimizes excess inventory and reduces waste. This approach not only aligns with sustainable practices but also improves inventory management.

Local Production: By enabling local production, 3D printing can cut down on shipping times and associated carbon footprints, promoting a more eco-friendly supply chain.

Enhanced Comfort and Performance

Customized Insoles and Orthotics: The ability to print custom insoles and orthotics means enhanced comfort and support tailored to individual needs, making footwear more functional and beneficial for specific activities.

Performance Optimization: Footwear designed with 3D printing can be optimized for various sports and activities, providing improved performance and comfort.

Collaborations and Innovations

Partnerships with Designers: Footwear brands are increasingly collaborating with designers to leverage 3D printing technology, resulting in unique, limited-edition collections that stand out in the market.

Technological Innovations: Recent advancements in 3D printing technology, such as multi-material printing and faster print speeds, are pushing the boundaries of what’s possible in footwear design and production.

Looking Ahead

As 3D printing continues to evolve, its impact on the footwear industry is set to grow. From personalized designs and sustainable practices to innovative materials and efficient production methods, the future of footwear is being shaped by this exciting technology.

The integration of 3D printing into the footwear industry is not just a trend; it represents a fundamental shift towards more personalized, sustainable, and efficient production methods. As the technology advances, it will likely continue to drive innovation and set new standards for the industry.